You’re sitting at your desk, with your hands on your head staring down at the balance sheet, burning the midnight oil again. You import promotional goods from China. You have an order of 20,000 pens currently in production and scheduled to leave the factory on December 15th – less than a week away.

You’re sitting at your desk, with your hands on your head staring down at the balance sheet, burning the midnight oil again. You import promotional goods from China. You have an order of 20,000 pens currently in production and scheduled to leave the factory on December 15th – less than a week away.

You have a choice to make. Do you save some money in the short run by skipping product inspection altogether? Or do you somehow allocate part of an already limited budget for inspection?

If you’ve manufactured goods before, especially abroad, I probably don’t have to tell you the value of carrying out product inspection of an order before shipping. Pre-shipment inspection is one of the only ways to ensure your products meet specifications and expectations for quality.

You might save a bit of money in the short term by forgoing inspection. But any issues with your finished product after it reaches distribution centers – or worse, your customers – might have you wishing you’d made the relatively small investment in quality control beforehand.

In this example, you work with tighter margins than importers buying high-ticket items like jewelry or furniture. How can you afford to spend a little extra on inspections to ensure the quality of the finished goods?

The answer: the same way the savviest importers do it. Here are five ways to cut inspection costs:

1. Decrease the sample size for inspection

A service that relies on AQL sampling uses established levels to determine the number of units to pull in a sample for inspection (learn more about three general inspection levels). Decreasing the sample size by lowering inspection level within the AQL framework is one of the most common and straightforward ways to cut inspection costs. And you can lower your inspection level while still having a random sample of goods checked.

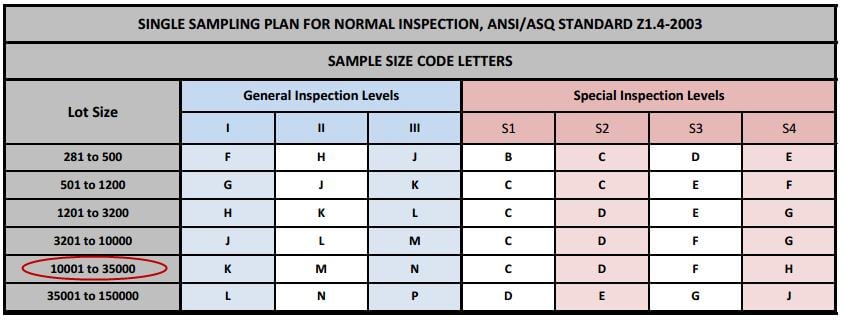

Your lot size is 20,000 pens, which gives you three options for general inspection levels, or sample sizes, below – “K”, “M” or “N”. You also have the option of choosing a “special inspection level”, a much smaller sample size that’s less frequently used.

If you look at the flip side of a standard AQL chart, you’ll see that sample size codes “K”, “M” and “N” correspond to 125, 315 and 500 units, respectively. This means that a GI-level inspection of your 20,000 pens will verify a sample of 125 pens. A GIII-level inspection would have the largest scope, verifying a sample of 500 pens of your order.

A larger sample size generally means inspection will take longer to complete. And a longer inspection will probably cost you more money if you’re hiring an independent auditor that bills on a man-day basis (see Third-Party Inspection vs. Factory Self-Inspection).

So the next time you receive a quote for product inspection, check the inspection level and consider lowering it if you’re on a tight budget. You can cut inspection costs simply by inspecting a smaller sample size.

"You can cut inspection costs by inspecting a smaller sample of product."2. Merge similar SKUs to inspect them as a group

It’s often possible to inspect a sample pulled from multiple SKUs grouped together and still get a fairly representative look at your order. SKUs that are similar enough can be combined and inspected as one without compromising the principle behind random sampling.

"SKUs that are similar enough can be combined and inspected as one."For example, let’s say your pens all have Marvel Comics characters painted on them. The only difference between SKUs is the different characters that are painted on each. Here your Spider-Man, Hulk, Iron Man and Captain America pens can all be merged into a single group. You'll save time, and therefore money, by inspecting a full sample size that is smaller than the sum of the four SKUs looked at separately.

But let’s say your Spider-Man and Hulk pens have a light that projects the shape of the comic character when the user holds down a button. Since this feature only applies to two out the four SKUs, it wouldn’t be wise to combine all four. Here you would be better off merging the two similar SKUs with the light feature as one group for sampling and the two similar SKUs without the light feature as a second group for sampling.

Merging SKUs is one way you can cut inspection costs. But you must be careful in choosing the SKUs that will be merged (learn more about merging SKUs).

3. Inspect based on time, rather than sample size

When you want the most units inspected in the shortest time possible you may choose to inspect based on time, rather than sample size. Instead of telling your QC provider to carry out a GI-level inspection of 125 units, you can ask them to simply inspect as many units as possible in one day. Inspecting this way can improve efficiency, but there’s one important drawback.

A product inspection based on time does not rely on statistical sampling using AQL.

"A product inspection based on time does not rely on statistical sampling using AQL."Without AQL sampling, the auditor inspecting your product is usually unable to provide a simple “pass” or “fail” inspection result. This is because statistically grounded AQL sampling determines the maximum number of defects allowed for a product to pass inspection. So an inspection result that doesn’t use AQL will be more difficult for you to interpret.

a simple “pass” or “fail” inspection result. This is because statistically grounded AQL sampling determines the maximum number of defects allowed for a product to pass inspection. So an inspection result that doesn’t use AQL will be more difficult for you to interpret.

Time-based inspection can help you cut inspection costs. But you should consider the effect of not using AQL sampling on your ability to make an informed shipping decision. This type of inspection is ill-advised if you’re inspecting an order for the first time.

4. Chargeback the supplier for failed inspections

Some importers will charge their suppliers for failed inspections. This is one way to cut inspection costs that might work for you. It can serve not only to keep inspection costs low, but also to incentivize your supplier to resolve quality issues. You may find you can curtail the number of inspections needed as your supplier tries even harder to avoid failing results.

But first you should carefully consider the relationship you have with your supplier before asking them to pay for failed inspections. You may have difficulty enforcing chargebacks in situations where:

- You’re ordering a relatively small quantity of an inexpensive product

- You’re working with a new supplier for the first time; or

- You have a history of problems getting your supplier to cooperate, particularly communication problems

In cases like these, trying to charge inspection costs to your supplier can be difficult. It can also hurt your relationship with the supplier and lead to more serious problems. This is a strategy best left to importers with a strong, long-standing relationship with their supplier or for importers with significant buying power and influence to negotiate with their supplier.

5. Inspect locally

The last way savvy importers cut inspection costs is by hiring a local auditor to inspect. It’s typically much more cost-effective to hire an auditor locally than to send someone who's based relatively far from the factory where the service is needed.

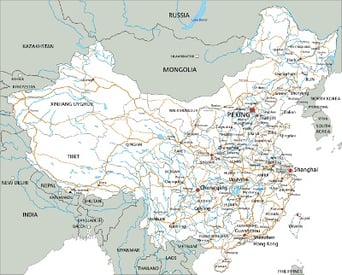

For example, maybe you have your own staff based in Hangzhou in China’s Zhejiang Province. But if you need your pens inspected at a factory in Jiangmen, Guangdong Province, an auditor from Hangzhou would need to travel about 1,350km to reach the inspection site. That means more time spent in transit and more travel expenses incurred.

For example, maybe you have your own staff based in Hangzhou in China’s Zhejiang Province. But if you need your pens inspected at a factory in Jiangmen, Guangdong Province, an auditor from Hangzhou would need to travel about 1,350km to reach the inspection site. That means more time spent in transit and more travel expenses incurred.

Whether you have your own full-time inspection staff or not, you can save a hefty sum by hiring an auditor near the inspection site to check your goods. In fact, many larger importers that have their own full-time QC team will rely on independent auditors or contractors for more remote areas (see Independent Inspection vs. In-House Inspection).

"You can save a hefty sum by hiring an auditor near the inspection site to check your goods."Conclusion

No business venture is risk-free. As an importer, you determine your own appetite for risk. But you can minimize your risk through pre-shipment inspection of your product. And you can keep these costs low, while protecting yourself from the risks of receiving substandard goods.

A small investment in quality control during the manufacturing process can pay dividends when your customers receive a product that meets quality expectations and requirements. As British designer Bruce Oldfield once said, “Never cut corners or accept anything that's second-rate.” You can cut inspection costs without cutting corners.

Check out the manufacturing podcast where John and George discuss the article!